+8613776545860

Fiberglass rebar, also known as GFRP (Glass Fiber Reinforced Polymer) rebar, has several advantages and disadvantages compared to traditional steel rebar.

Advantages of fiberglass rebar include:

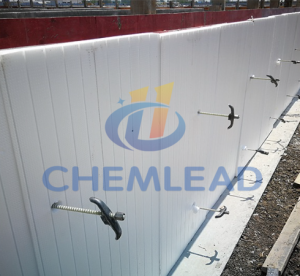

1. Corrosion resistance: Fiberglass rebar does not rust or corrode like steel rebar, making it ideal for use in environments where corrosion is a concern, such as marine or chemical environments. Corrosion resistance is a hallmark feature of fiberglass rebar, distinguishing it from traditional steel reinforcement in construction applications. Fiberglass rebar is crafted from a composite material comprising high-strength glass fibers embedded within a polymer resin matrix. This unique composition grants fiberglass rebar exceptional resistance to corrosion, ensuring structural integrity and longevity in various environments.

2. Lightweight: Fiberglass rebar is significantly lighter than steel rebar, which can make handling and installation easier and reduce labor costs. Fiberglass rebar is significantly lighter than steel rebar of comparable strength, making it easier to handle, transport, and maneuver on construction sites. This lightweight nature reduces the physical strain on workers during installation, leading to increased efficiency and productivity. The low weight of fiberglass rebar results in reduced structural loading on concrete elements. This is particularly advantageous in projects where weight restrictions or concerns about excessive loads on structures are paramount, such as in seismic zones or when retrofitting existing buildings.

3. Non-conductive: Fiberglass rebar does not conduct electricity, which can be beneficial in applications where electrical conductivity is a concern, such as in structures near power lines. Fiberglass rebar is ideal for use in structures where electrical conductivity poses a risk, such as bridges, tunnels, or buildings with electrical installations. Its non-conductive nature reduces the likelihood of electrical accidents, shock hazards, or electromagnetic interference, enhancing overall safety for workers and occupants.

4. Thermal properties: Fiberglass rebar has lower thermal conductivity than steel rebar, which can help reduce thermal bridging and minimize temperature-related stresses in concrete structures. Fiberglass rebar exhibits low thermal conductivity compared to steel rebar. This property reduces the transfer of heat through the reinforcement, making it suitable for applications where thermal insulation is desired. In structures such as cold storage facilities or buildings in extreme climates, fiberglass rebar helps maintain stable internal temperatures and minimizes thermal bridging, improving energy efficiency and comfort.

5. High tensile strength: Fiberglass rebar has a high tensile strength, similar to steel rebar, allowing it to effectively reinforce concrete structures…

Fiberglass rebar have a higher strength-to-weight ratio compared to steel rebar, meaning it can provide equivalent strength with less material. Additionally, fiberglass rebar does not rust or corrode like steel rebar, making it suitable for use in corrosive environments. While fiberglass rebar can offer comparable strength to steel rebar, engineers and designers must consider other factors such as cost, durability, and compatibility with concrete mixes when selecting the appropriate reinforcement material for a specific project.

Fiberglass rebar can also offer a durable and reliable reinforcement solution for concrete structures, especially in environments where corrosion is a concern. With proper installation and maintenance, fiberglass rebar can contribute to the long-term integrity and performance of reinforced concrete elements…

Contact info@chemlead-frp.com for more and get a quote!

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!