+8613776545860

The Future of Construction: Basalt Fiberglass & Basalt Rebar

In the ever-evolving world of construction and engineering, basalt fiberglass and basalt rebar are gaining significant attention for their strength, durability, and sustainability. These innovative materials are revolutionizing industries by providing high-performance alternatives to traditional construction materials.

What is Basalt Fiberglass?

Basalt fiberglass is a high-performance material derived from natural basalt rock. The rock is melted at high temperatures and then extruded into fine fibers, which are then processed into various forms, including reinforcement materials.

Key Benefits of Basalt Fiberglass:

– High Strength-to-Weight Ratio – Stronger than steel yet significantly lighter, making it easier to handle and transport.

– Corrosion Resistance – Unlike steel, basalt fiberglass does not rust or corrode, making it ideal for harsh environments.

– Thermal and Chemical Stability – Can withstand extreme temperatures and resist chemical degradation.

– Eco-Friendly – Made from natural volcanic rock, basalt fiberglass has a lower carbon footprint than synthetic alternatives.

Basalt Rebar: The Future of Reinforcement

Basalt rebar is an advanced alternative to traditional steel rebar in construction. It is made by combining basalt fibers with polymer resin, resulting in a reinforcement material that outperforms steel in many aspects.

Advantages of Basalt Rebar:

– Superior Strength & Durability – Higher tensile strength compared to steel rebar, ensuring long-term structural integrity.

– Corrosion-Free – Does not rust, making it ideal for marine structures, bridges, and chemical plants.

– Lightweight & Easy to Install – Up to 4 times lighter than steel, reducing labor and transportation costs.

– Non-Conductive & Non-Magnetic – Ideal for applications where electromagnetic neutrality is essential, such as in medical or military installations.

– Longevity & Cost-Effectiveness– Offers a longer lifespan with minimal maintenance, reducing overall project costs.

Applications of Basalt Fiberglass & Basalt Rebar

1. Infrastructure & Bridges – Enhanced durability and resistance to harsh weather conditions.

2. Highways & Road Construction – Prevents cracking and extends pavement life.

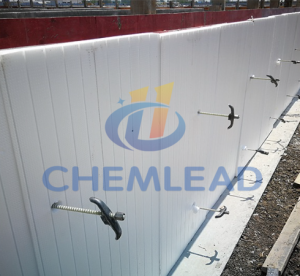

3. Marine & Coastal Structures – Resists saltwater corrosion, making it ideal for piers, docks, and seawalls.

4. Residential & Commercial Buildings – Improves building strength while reducing overall weight.

5. Tunnels & Underground Structures– Non-corrosive nature ensures longevity in moisture-prone environments.

Why the Industry is Shifting to Basalt Materials

The construction industry is increasingly adopting basalt-based materials due to their environmental benefits, cost-effectiveness, and superior performance compared to traditional options. With growing concerns about sustainability and the rising costs of steel, basalt fiberglass and basalt rebar are emerging as game changers for the future of construction.

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!