+8613776545860

FRP Foam Boards: The New Trend in Construction and Insulation Materials

In modern construction, insulation and thermal performance have become increasingly important, especially in the context of energy efficiency and environmental sustainability. To enhance the energy performance of buildings, many new materials have emerged, with FRP foam boards and polyurethane foam gaining popularity due to their excellent thermal insulation properties, durability, and versatile applications. This blog will explore the features, applications, and advantages of FRp foam boards and polyurethane foam, helping you understand why these materials are becoming essential in modern construction.

What Are FRP Foam Boards?

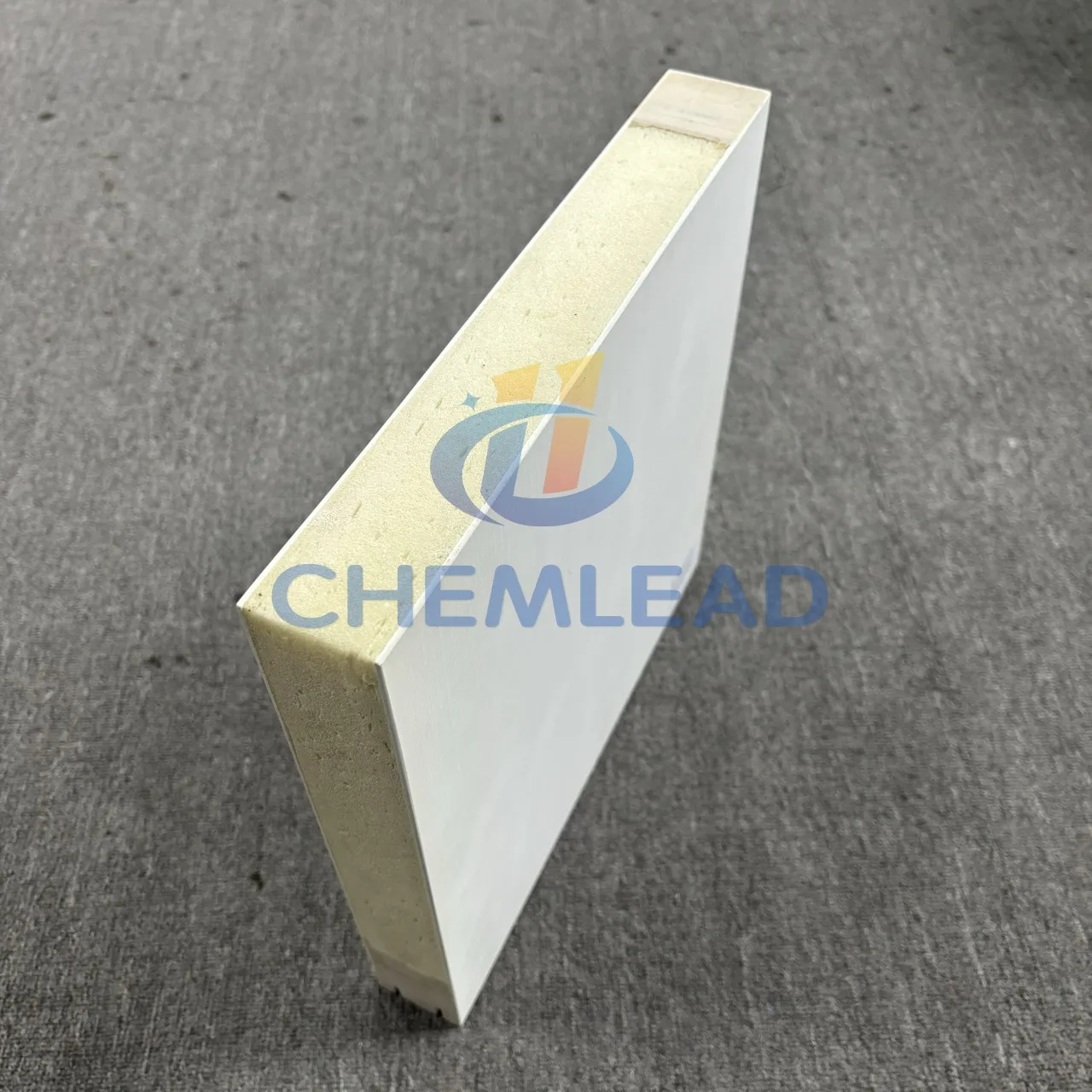

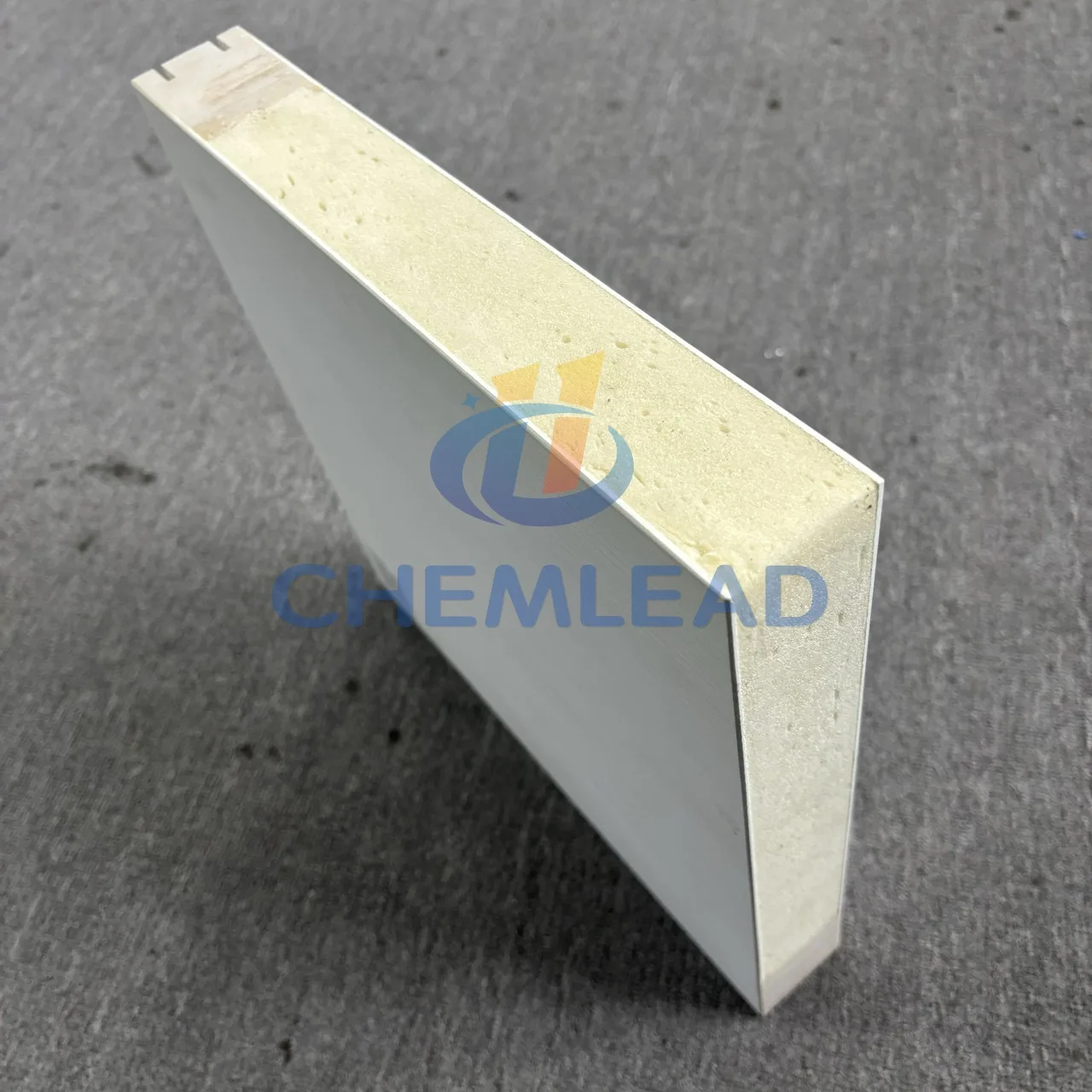

FRP (Fiberglass Reinforced Plastic) foam boards are composite panels made by combining glass fiber with a foam material. The core of an FRP foam board is usually made from polyurethane, phenolic foam, or other similar materials, which undergo a chemical reaction to form a closed-cell structure. This closed-cell structure not only provides excellent insulation but also enhances the material’s strength and durability. The addition of glass fiber gives the board enhanced tensile strength, corrosion resistance, and a longer service life.

Features of FRP Foam Boards

1.Excellent Thermal Insulation: The foam core of FRP foam boards creates a network of closed air cells that effectively block heat transfer and moisture infiltration, improving the thermal insulation performance.

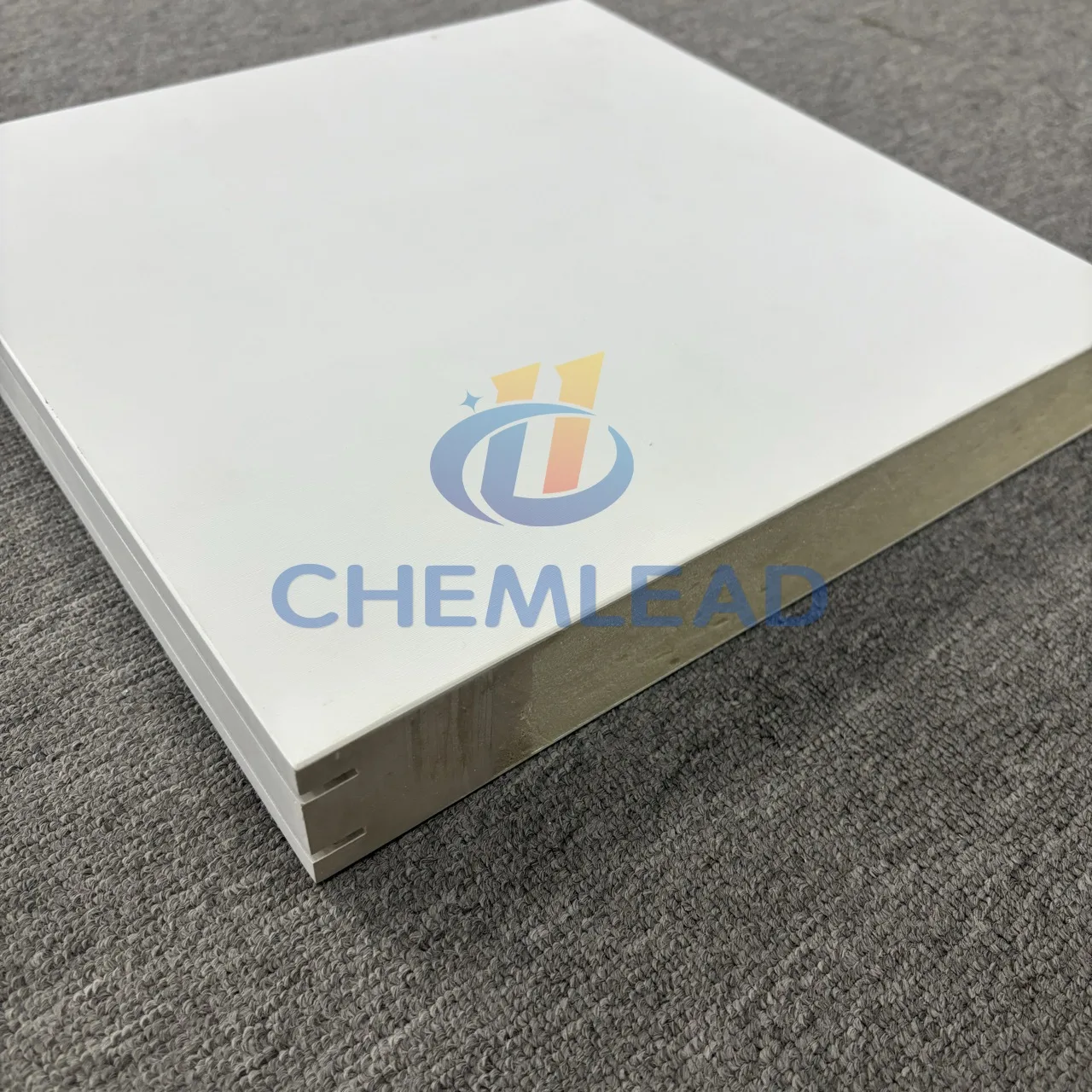

2.Lightweight and High Strength: The glass fiber reinforcement makes the FRP foam board strong yet lightweight, providing both superior mechanical strength and ease of handling and installation.

3.Corrosion Resistance: The glass fiber component enhances the material’s resistance to corrosion, making it suitable for use in challenging environments such as coastal areas or chemical processing plants.

4.Fire Resistance: Many FRP foam boards are treated to meet fire safety standards, offering excellent fire resistance and ensuring compliance with stringent building codes.

5.Environmental Friendliness: FRP foam boards are often made from recyclable materials and contribute to sustainable building practices, reducing the overall environmental impact.

Applications of FRP Foam Boards

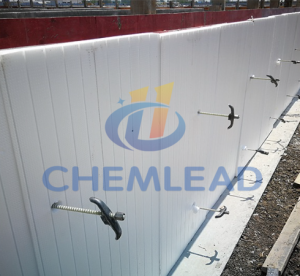

•Building Facades and Walls: Due to their excellent insulation properties, FRP foam boards are widely used in the exterior cladding, walls, roofs, and window frames of buildings for thermal insulation.

•Cold Storage and Refrigeration: The low thermal conductivity of FRP foam boards makes them ideal for cold storage rooms, refrigerated vehicles, and other temperature-sensitive environments.

•Transportation: FRP foam boards are commonly used in refrigerated trucks, containers, and other transport vehicles, ensuring goods stay at the desired temperature.

•Chemical and Wastewater Treatment Facilities: Their corrosion-resistant properties make FRP foam boards an ideal choice for chemical plants, water treatment facilities, and other environments exposed to harsh chemicals or moisture.

What is Polyurethane Foam?

Polyurethane foam is a foam material created through a chemical reaction between polyols (resins) and isocyanates, often with the addition of blowing agents and catalysts. Depending on the chemical composition and manufacturing process, polyurethane foam can be produced as either flexible or rigid foam. In the construction industry, rigid polyurethane foam is primarily used for thermal insulation, applied in the form of foam boards, spray foam, and other insulation products.

Features of Polyurethane Foam

1.Excellent Insulation Properties: Polyurethane foam is one of the best insulation materials available today due to its low thermal conductivity. It effectively reduces heat transfer, ensuring buildings remain energy-efficient and reducing heating and cooling costs.

2.Water Resistance: The closed-cell structure of polyurethane foam provides excellent water resistance, making it ideal for areas exposed to moisture and ensuring long-term durability.

3.Lightweight and High Strength: Polyurethane foam is lightweight yet strong, reducing the overall weight of the structure and making installation easier and faster.

4.Sealing Properties: Polyurethane foam is often used for sealing gaps and cracks in buildings, preventing air, heat, and moisture from escaping, which further enhances the energy efficiency of the building.

5.Long-lasting Durability: Polyurethane foam is highly durable, resistant to aging, and can withstand harsh weather conditions. This results in a longer service life with minimal maintenance.

Applications of Polyurethane Foam

1.Building Insulation: Polyurethane foam is widely used for insulating walls, roofs, floors, and ceilings in both residential and commercial buildings. It plays a key role in reducing energy consumption and improving thermal comfort.

2.Cold Chain Logistics: Polyurethane foam is used extensively in cold storage rooms, refrigerated vehicles, and containers, ensuring that temperature-sensitive goods are kept at the proper temperature.

3.Pipe Insulation: Polyurethane foam is commonly used for insulating hot and cold water pipes, HVAC ducts, and other piping systems, preventing energy loss and reducing the risk of freezing.

4.Automotive and Transportation: Polyurethane foam is used in automotive applications, including seat cushions, interior parts, and insulation in refrigerated vehicles, contributing to comfort and thermal control.

Comparing FRP Foam Boards and Polyurethane Foam

Feature FRP Foam Boards Polyurethane Foam

Insulation Properties Excellent, ideal for high-performance applications Outstanding, especially for energy-efficient buildings

Water Resistance Excellent, prevents moisture infiltration Excellent, resists water penetration

Corrosion Resistance High, suitable for harsh environments Moderate, best for typical building environments

Strength High, suitable for structural applications High, ideal for building insulation and pipes

Applications Building facades, cold storage, transportation Building insulation, cold chain logistics, pipes

Environmental Impact Eco-friendly, often recyclable Highly efficient and sustainable, low environmental impact

Conclusion

Both FRP foam boards and polyurethane foam represent significant advancements in thermal insulation and construction materials. Offering excellent thermal performance, durability, and versatility, these materials are indispensable in energy-efficient buildings, cold storage facilities, and various industrial applications. When choosing between the two, it’s essential to consider specific project requirements, environmental conditions, and long-term performance.

As the construction industry moves towards more sustainable and energy-efficient solutions, FRP foam boards and polyurethane foam are paving the way for smarter, greener buildings. Whether you’re working on a residential, commercial, or industrial project, these materials are sure to provide significant benefits in terms of energy savings, durability, and overall performance.

If you’re interested in learning more about these materials or how they can be integrated into your projects, feel free to reach out. We’re here to provide expert guidance and help you choose the right insulation solution for your needs!

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!