+8613776545860

Understanding Fiberglass Form Ties: Revolutionizing Concrete Formwork

When it comes to concrete construction, formwork plays a crucial role in shaping the concrete until it sets. Among the various components of formwork systems, form ties are essential elements that maintain the structural integrity and alignment of concrete forms during the pouring process. While traditional form ties have historically been made of metal, a new innovation is changing the game: fiberglass form ties.

In this blog, we will explore what fiberglass form ties are, how they work, and the advantages they offer over conventional metal ties. Whether you are a contractor, engineer, or someone interested in construction materials, this guide will help you understand why fiberglass form ties are gaining popularity in the concrete industry.

What Are Fiberglass Form Ties?

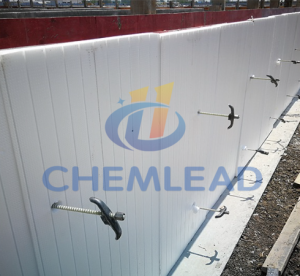

Fiberglass form ties are a type of formwork accessory used to secure the form panels together during the pouring and curing of concrete. These ties are designed to keep the two sides of the form in place, ensuring the concrete structure is stable as it hardens. Unlike traditional metal form ties, which are often made of steel or aluminum, fiberglass form ties use a composite material that combines glass fibers with a resin matrix, resulting in a highly durable, lightweight, and non-corrosive product.

Fiberglass form ties are generally available in different lengths, diameters, and load-bearing capacities to suit various types of concrete projects, including walls, foundations, and other structural elements.

How Do Fiberglass Form Ties Work?

Fiberglass form ties are used to connect the two opposing form panels (often made of wood, steel, or plastic) and maintain the desired spacing between them. Here’s how the process typically works:

1.Installation: The fiberglass form tie is placed through the form panels at designated points, and the ends are secured to prevent them from moving during the concrete pouring process. These ties help to maintain the correct distance between the two form panels, ensuring the right thickness for the concrete structure.

2.Concrete Pouring: Once the formwork is in place and the fiberglass ties are securely positioned, the concrete is poured into the forms. The fiberglass ties help to keep the formwork stable as the concrete is poured, even under the pressure of the wet mix.

3.Curing: After the concrete is poured, it begins to set and cure. The form ties hold the panels in position, ensuring the concrete structure takes the desired shape. Once the concrete has hardened, the form panels are removed, leaving behind the completed structure.

4.Tie Removal: Unlike traditional metal ties that often need to be cut or removed with specialized tools, fiberglass form ties are typically designed to break or snap off easily when the formwork is removed. Some fiberglass form ties leave a minimal embedded footprint, while others can be fully extracted if needed.

Advantages of Fiberglass Form Ties

1.Corrosion Resistance: One of the primary advantages of fiberglass form ties is their resistance to corrosion. Unlike metal form ties, fiberglass is impervious to moisture, chemicals, and other environmental elements that can cause rust and deterioration. This is particularly beneficial for projects in coastal areas, underground structures, or locations with high humidity.

2.Lightweight and Easy to Handle: Fiberglass ties are much lighter than their metal counterparts, making them easier to transport, handle, and install. This reduces the overall labor costs and time required for formwork assembly.

3.Durability and Strength: Despite being lightweight, fiberglass is incredibly strong and durable. Fiberglass form ties can withstand high tensile loads without breaking or deforming. This ensures that the formwork remains intact and that the concrete structure is properly shaped during the curing process.

4.Non-Conductive: Unlike metal ties, fiberglass is a non-conductive material, making it safer to use in areas where electrical safety is a concern. This makes fiberglass form ties an excellent choice for projects near power lines or electrical equipment.

5.Longer Lifespan: Because fiberglass does not corrode like metal, fiberglass form ties typically have a longer lifespan. This means fewer replacements and lower overall maintenance costs, which is a huge benefit for long-term construction projects.

6.Environmental Benefits: Fiberglass form ties are often made from recyclable materials, making them a more eco-friendly option compared to traditional metal form ties. Additionally, the longevity and durability of fiberglass reduce the need for frequent replacements, which can contribute to less waste in the long run.

7.Cost-Effective in the Long Run: While fiberglass form ties may have a slightly higher upfront cost compared to steel or plastic form ties, their durability, corrosion resistance, and reduced maintenance needs often make them more cost-effective over the course of a project or multiple projects.

Applications of Fiberglass Form Ties

Fiberglass form ties are used in a variety of concrete construction applications, including:

•Residential and Commercial Buildings: For foundations, walls, and other structural elements that require formwork.

•Tunnels and Underground Structures: Where the risk of corrosion from moisture and chemicals is high.

•Bridges and Overpasses: In areas exposed to harsh weather conditions and de-icing chemicals.

•Water Treatment Plants: In facilities that deal with water or wastewater, where corrosion resistance is critical.

Conclusion

Fiberglass form ties are transforming the way concrete construction is carried out. Offering superior durability, corrosion resistance, and ease of use, they have become an essential tool in modern formwork systems. With their lightweight construction, strength, and long lifespan, fiberglass form ties provide significant benefits over traditional metal ties.

Whether you’re involved in residential, commercial, or industrial construction, fiberglass form ties are an investment that will pay off in terms of time, labor, and overall durability. As the construction industry continues to evolve, these advanced materials will undoubtedly play a key role in shaping the future of concrete formwork.

If you’re considering upgrading your formwork system, switching to fiberglass form ties might just be the solution your project needs!

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!