+8613776545860

When it comes to construction and infrastructure projects, durability and strength are key considerations. One material that has gained significant popularity in recent years is fiberglass rebar mesh. This advanced construction material provides a modern solution to challenges that steel reinforcement faces, especially in environments where corrosion is a major concern. In this blog, we’ll dive deep into the world of fiberglass rebar mesh—its benefits, applications, and why it should be your go-to material for your next project.

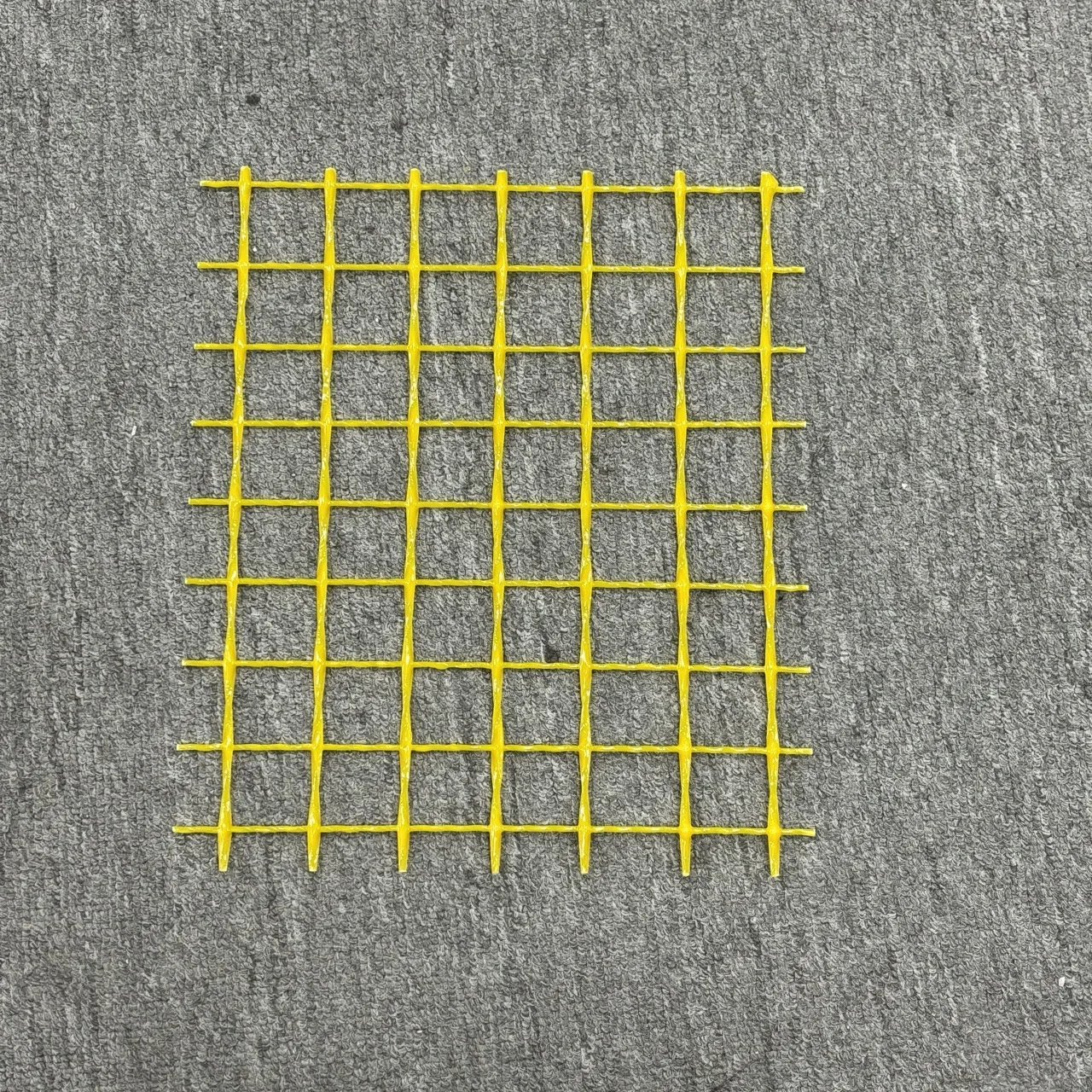

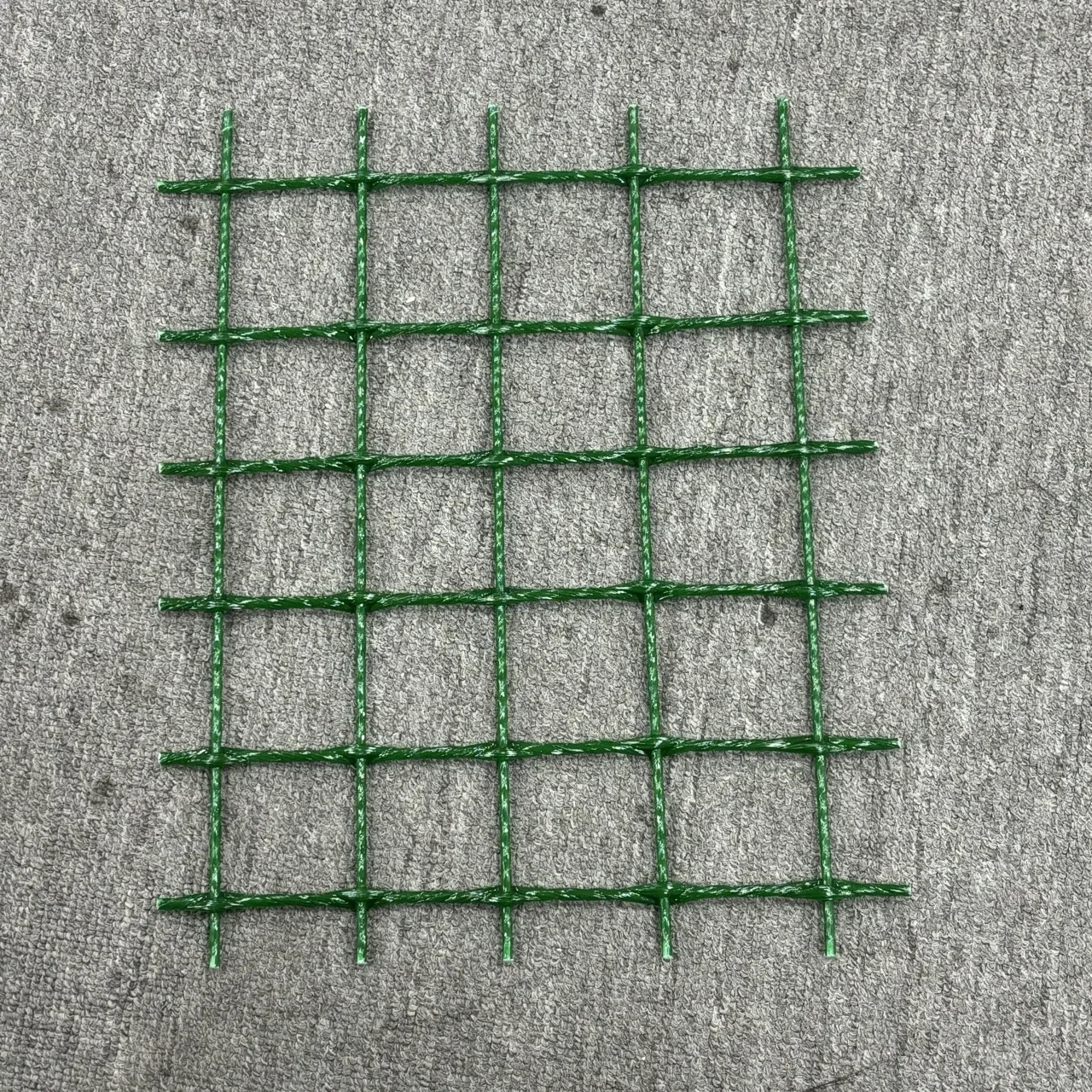

What Is Fiberglass Rebar Mesh?

Fiberglass rebar mesh, also known as glass fiber reinforced polymer (GFRP) mesh, is a composite material made from glass fibers and resin. The fibers are arranged in a grid-like pattern and bonded together with a durable resin. This mesh is used as reinforcement in concrete structures, similar to traditional steel rebar, but with numerous added benefits that make it an appealing alternative in specific environments.

Key Benefits of Fiberglass Rebar Mesh

1. Corrosion Resistance

One of the standout features of fiberglass rebar mesh is its excellent resistance to corrosion. Unlike steel rebar, which can rust over time when exposed to moisture, salts, and chemicals, fiberglass remains unaffected. This makes it an ideal choice for projects in coastal or highly humid areas, as well as places that are regularly exposed to harsh chemicals.

2. Lightweight and Easy to Handle

Fiberglass rebar mesh is significantly lighter than steel, making it easier to transport and install. Despite being lightweight, it retains impressive strength, making it perfect for large-scale projects where both durability and ease of use are critical.

3. High Tensile Strength

Don’t let its lightweight nature fool you—fiberglass rebar mesh offers excellent tensile strength, which helps in distributing loads evenly across the structure. This makes it highly effective in reducing the risk of cracking in concrete over time.

4. Non-Conductive

Another unique advantage of fiberglass rebar mesh is that it does not conduct electricity. This feature makes it the preferred reinforcement material in structures that are sensitive to electromagnetic fields, such as hospitals, laboratories, and power plants.

5. Thermal Stability

Fiberglass rebar mesh maintains its structural integrity across a wide temperature range, which is crucial for projects in regions with extreme weather conditions. It doesn’t warp or weaken when exposed to high or low temperatures, ensuring long-lasting performance.

6. Longer Lifespan

With its resistance to corrosion and chemical attack, fiberglass rebar mesh offers a much longer lifespan compared to steel. This results in reduced maintenance costs and fewer repairs over the lifetime of the structure, making it a cost-effective solution in the long term.

Applications of Fiberglass Rebar Mesh

Fiberglass rebar mesh has a wide range of applications, particularly in environments where steel may not be the most effective option. Here are some of the most common uses:

1. Marine and Coastal Structures

Seawater and saline environments are notorious for corroding steel, making fiberglass rebar mesh the preferred reinforcement material for docks, seawalls, and other coastal structures. Its corrosion resistance ensures longevity in these harsh environments.

2. Roads, Bridges, and Tunnels

In infrastructure projects such as roads, bridges, and tunnels, where durability and low maintenance are essential, fiberglass rebar mesh helps extend the life of these structures. Additionally, its lightweight nature makes installation quicker and more efficient.

3. Industrial Facilities

Chemical plants, factories, and other industrial facilities often expose construction materials to aggressive chemicals. Fiberglass rebar mesh offers protection against these corrosive substances, ensuring that the structural integrity of buildings remains intact.

4. Electrical and Magnetic Applications

Due to its non-conductive properties, fiberglass rebar mesh is used in environments that require insulation from electrical currents, such as power plants, laboratories, and certain types of manufacturing facilities.

5. Residential and Commercial Buildings

For residential and commercial construction, particularly in areas prone to extreme weather or seismic activity, fiberglass rebar mesh provides the needed reinforcement to support walls, floors, and foundations while resisting environmental stresses.

Why Choose Fiberglass Rebar Mesh Over Steel?

While steel has long been the traditional choice for concrete reinforcement, fiberglass rebar mesh is steadily gaining traction due to its superior properties in certain applications. If you’re working on a project where corrosion, chemical exposure, or electrical conductivity are concerns, switching to fiberglass can improve the structure’s durability and longevity. Additionally, the ease of handling and reduced labor costs associated with fiberglass mesh make it an attractive alternative in terms of project efficiency.

Conclusion

Fiberglass rebar mesh is a game-changer in the construction industry, offering numerous benefits over traditional steel reinforcement, especially in challenging environments. From marine and coastal structures to industrial facilities and residential buildings, its corrosion resistance, high tensile strength, and thermal stability make it the perfect reinforcement material for a variety of applications.

If you’re looking to enhance the durability and performance of your next construction project, consider choosing fiberglass rebar mesh. With its long-lasting benefits and superior performance, it’s the smart choice for modern infrastructure.

Interested in learning more about how fiberglass rebar mesh can benefit your project? Contact us today for expert advice and solutions tailored to your specific needs.

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!