+8613776545860

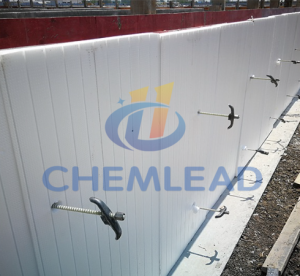

Busy Loading Day for Our Fiberglass Rebar Today!

Why Fiberglass Rebar?

Fiberglass rebar is a strong, durable, and corrosion-resistant alternative to traditional steel rebar. It is made from a composite of glass fibers and resin, and is typically used in concrete construction. Fiberglass rebar is lighter and easier to handle than steel rebar, and it is also non-conductive, making it a safer choice for use in electrical environments.

Benefits of Using Fiberglass Rebar

- Stronger and more durable than steel rebar

- Corrosion-resistant

- Non-conductive

- Lighter and easier to handle

- Environmentally friendly

How Fiberglass Rebar Is Made

Fiberglass rebar is made from a continuous process that involves pulling glass fibers through a resin bath and then curing them. The result is a strong, durable, and flexible rod that can be used in a variety of applications.

Applications of Fiberglass Rebar

Fiberglass rebar can be used in a variety of applications, including:

- Concrete construction

- Bridge construction

- Marine construction

- Industrial construction

- Residential construction

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!