+8613776545860

Introduction

Sheet Molding Compound (SMC) has emerged as a cornerstone material in various industries due to its exceptional combination of strength, lightweight properties, and durability. This composite material is produced by blending long fiberglass strands with resin, fillers, and additives, resulting in sheets that can be molded into intricate shapes.

Key Features of SMC

Unmatched Strength and Durability: SMC’s robust structure makes it ideal for applications demanding high performance and resistance to wear and tear.

Lightweight Champion: Despite its strength, SMC is remarkably lightweight, a critical advantage in industries prioritizing weight reduction, such as automotive and aerospace.

Corrosion Defiance: SMC’s inherent resistance to corrosion ensures its longevity in challenging environments.

Design Flexibility: This versatile material can be molded into complex shapes, opening doors for innovative product designs.

Real-World Applications

SMC’s impressive properties have found applications across diverse sectors:

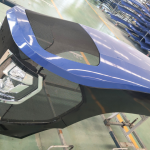

Automotive Industry: A major consumer of SMC, the automotive industry leverages this material for manufacturing essential components like bumpers, hoods, and body panels.

Electrical Components: SMC’s electrical insulating properties make it a preferred choice for enclosures, insulators, and switchgear.

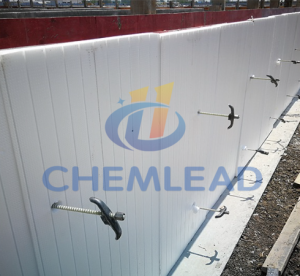

Construction and Building: Roofing products, bathroom fixtures, and wall panels benefit from SMC’s durability and weather resistance.

Aerospace: The aerospace industry utilizes SMC for crafting lightweight yet strong interior panels and structural components.

Conclusion

SMC’s unique blend of strength, lightness, and durability positions it as a prime material for a wide range of applications. Its ability to be molded into complex shapes further enhances its versatility. As technology advances, we can anticipate even more groundbreaking applications of SMC, solidifying its status as a key player in the materials science landscape.

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!