+8613776545860

Introduction

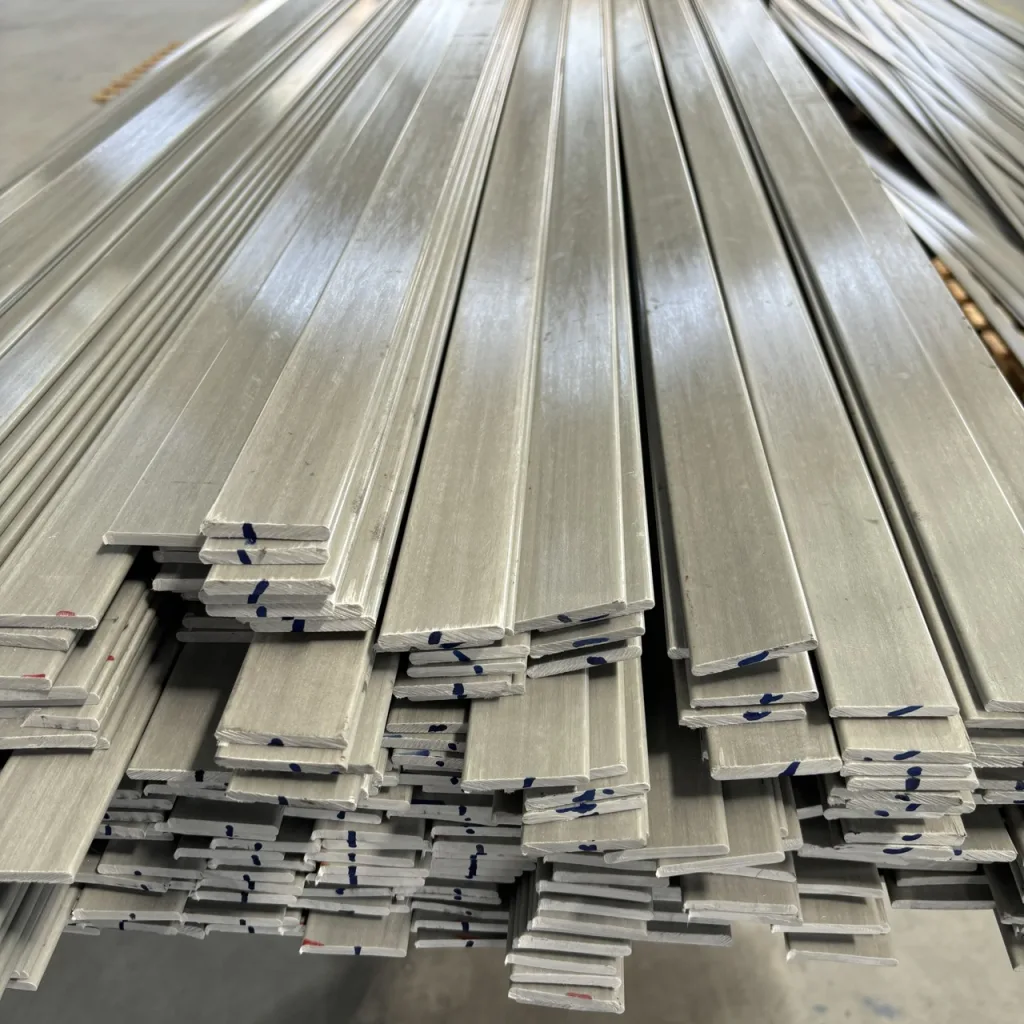

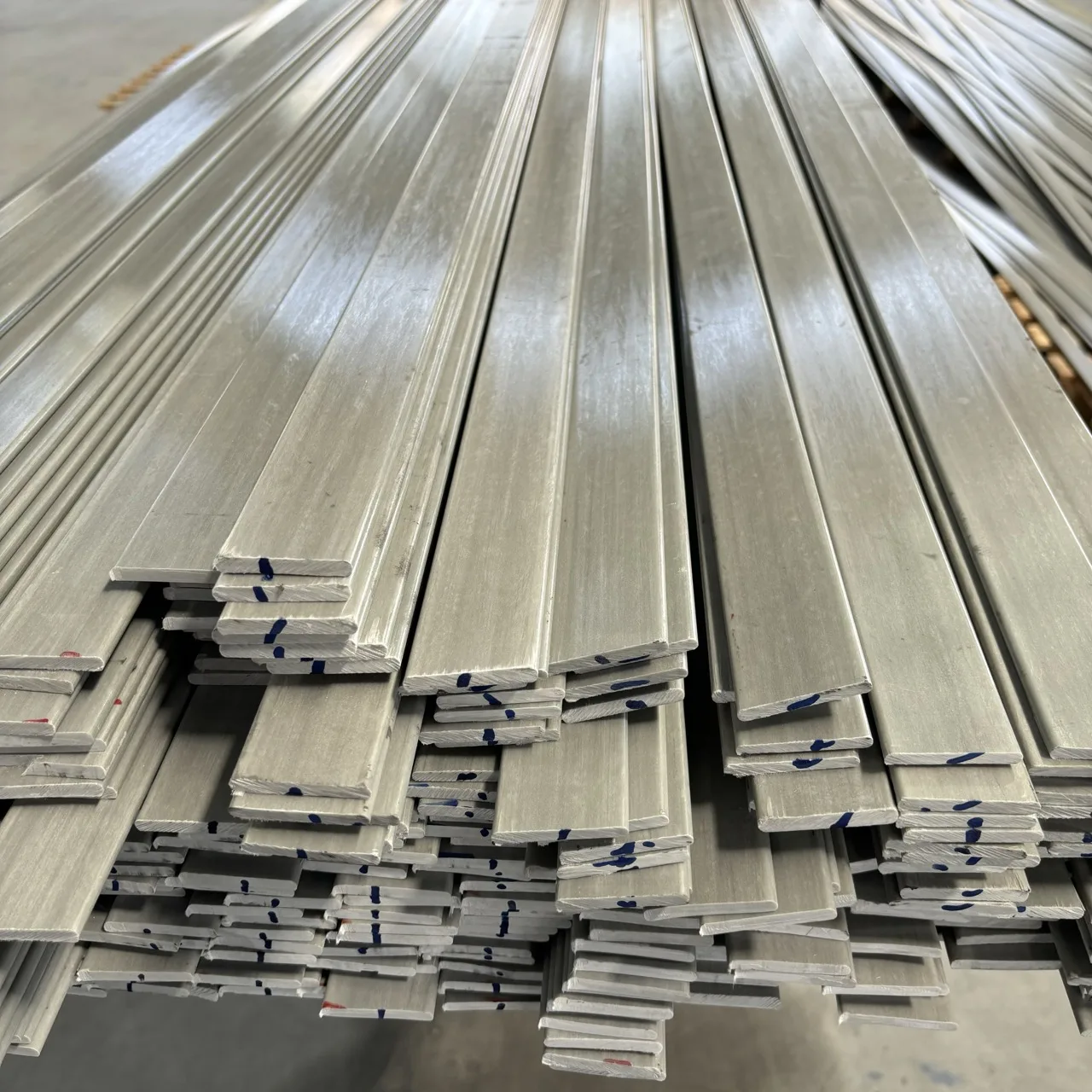

Fiberglass strips, renowned for their durability, flexibility, and resistance to harsh conditions, have found their way into a myriad of applications across various industries. From construction and electrical insulation to aerospace and sports equipment, these unassuming strips have proven to be invaluable components in modern manufacturing and engineering. Let’s delve into the diverse world of fiberglass strip applications.

The Many Uses of Fiberglass Strips

Reinforcement and Structural Integrity

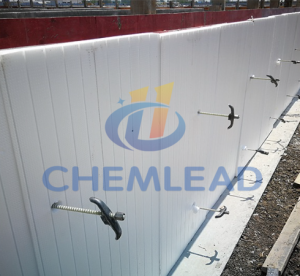

Fiberglass strips excel at enhancing the strength and durability of materials. In construction, they are commonly used to reinforce concrete, plastics, and other building components. Their role extends to the aerospace industry, where they contribute to the lightweight yet robust structure of aircraft.

Electrical Insulation and Protection

Thanks to their non-conductive properties,fiberglass strips are indispensable in electrical insulation. They safeguard wiring, transformers, and other electrical components from short circuits and potential hazards.

Repair and Restoration

The marine and automotive sectors rely on fiberglass strips for repairing and reinforcing damaged components. Their ability to withstand harsh environments makes them ideal for restoring boats and vehicles to their former glory.

Composite Materials and Beyond

Fiberglass strips are essential in the creation of composite materials, offering increased strength and rigidity to products ranging from panels and doors to sports equipment like surfboards and skis. Even wind turbines benefit from the incorporation of fiberglass strips for enhanced structural integrity.

Conclusion

The versatility of fiberglass strips is truly remarkable. Their unique combination of properties makes them a preferred choice in numerous industries. As technology continues to advance, we can expect to see even more innovative applications emerge for this versatile material.

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!