+8613776545860

Rebar Revolution: Choosing the Right Fiberglass Option for Your Project

Fiberglass rebar has emerged as a compelling alternative to traditional steel rebar in concrete construction. But with various fiberglass types available, selecting the most suitable option can be tricky. This blog dives into the key differences between polyester, vinyl ester, and epoxy fiberglass rebar, empowering you to make informed decisions for your next project.

The Benefits of Fiberglass Rebar

Before we explore the specific types, let’s revisit the general advantages fiberglass rebar offers over steel:

- Lightweight: Significantly lighter than steel, fiberglass rebar simplifies transportation, handling, and construction.

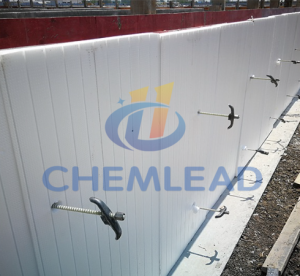

- Corrosion Resistant: Unlike steel, fiberglass is immune to rust, increasing the longevity and reducing maintenance needs of concrete structures.

- Thermally Efficient: Fiberglass’s lower thermal conductivity minimizes heat transfer in concrete, improving energy efficiency.

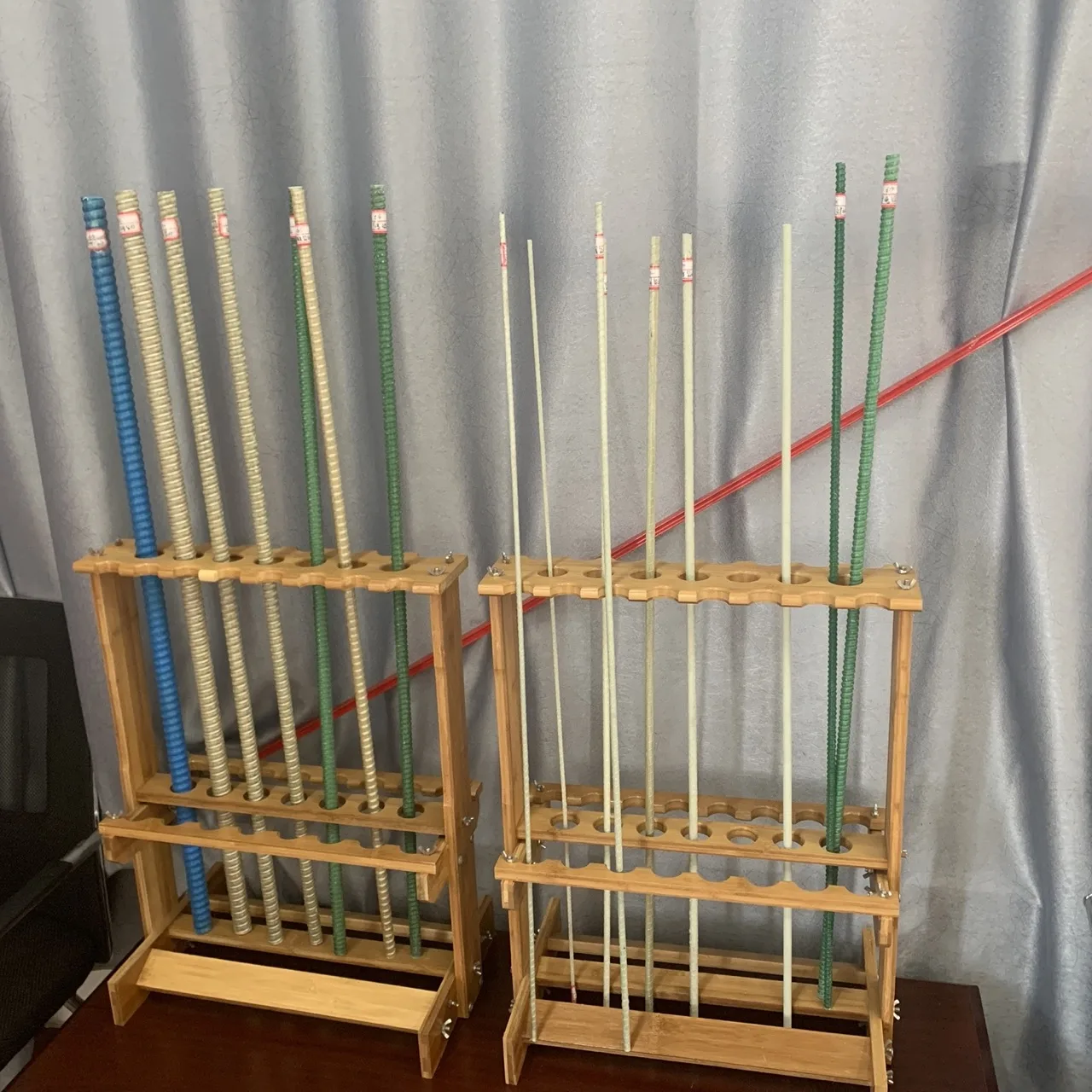

Understanding the Fiberglass Rebar Variations

Now, let’s delve into the three main fiberglass rebar options:

Polyester Rebar: The most economical choice, polyester rebar is ideal for non-structural applications like concrete patching or low-stress foundations. It boasts good chemical resistance for everyday environments.

Vinyl Ester Rebar: Striking a balance between affordability and performance, vinyl ester rebar is suitable for structures with moderate stress or potential exposure to mild chemicals.

Epoxy Rebar: The strongest and most durable of the three, epoxy rebar excels in high-stress applications like beams, slabs, and retaining walls. It provides superior chemical resistance, making it perfect for harsh environments like marine or industrial settings.

A Helpful Table for Comparison

Here’s a quick reference table summarizing the key points:

| Feature | Polyester | Vinyl Ester | Epoxy |

|---|---|---|---|

| Strength | Low | Medium | High |

| Durability | Low | Medium | High |

| Chemical Resistance | Low | Medium | High |

| Cost | Low | Medium | High |

| Applications | Non-structural, low-stress | Moderate stress, some chemical exposure | High-stress, harsh environments |

Choosing the Right Fiberglass Rebar

The ideal fiberglass rebar type depends on your project’s specific requirements. Consider these factors:

- Strength Demands: High-stress applications necessitate strong options like epoxy.

- Chemical Exposure: For harsh environments, superior chemical resistance of vinyl ester or epoxy is crucial.

- Budgetary Constraints: Polyester offers the most cost-effective solution for low-stress projects.

Remember:

- Local building codes may have regulations regarding fiberglass rebar usage.

- Consulting a structural engineer is vital to determine the appropriate rebar type and quantity for your project.

By understanding the distinctions between polyester, vinyl ester, and epoxy fiberglass rebar, you’re well-equipped to make informed decisions for your construction needs. Fiberglass rebar offers a lightweight, corrosion-resistant, and thermally efficient alternative to steel, making it a valuable addition to the modern builder’s toolbox.

Want to Learn More?

If you have further questions about fiberglass rebar or other construction materials, feel free to contact us!

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!