+8613776545860

Concrete may be incredibly strong, but on its own, it lacks the tensile strength needed to withstand significant pressure or bending. That’s where reinforcement bars, or rebar, come in. Traditionally, steel rebar has been the go-to for reinforcing concrete. However, a challenger has emerged: fiberglass rebar.

So, when it comes to your next project, which material reigns supreme? Let’s break down the key differences between steel and fiberglass rebar to help you decide.

Strength and Weight: A Steel Tradition, a Fiberglass Future

Steel rebar boasts a long history of reliable performance. Its high tensile strength makes it ideal for projects requiring maximum reinforcement. However, this strength comes at a cost: weight. Steel rebar is heavy, making transportation and installation labor-intensive.

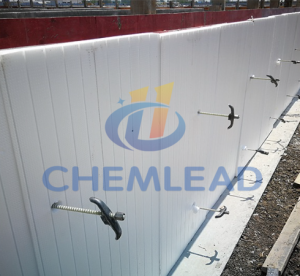

Fiberglass rebar offers a lighter alternative. Made from high-strength glass fibers embedded in a polymer resin, fiberglass rebar is significantly lighter than steel. This translates to easier handling, faster installation, and potentially lower labor costs. However, while some fiberglass options offer comparable tensile strength to certain steel grades, it’s important to consult with engineers to ensure the chosen fiberglass rebar meets project specifications.

Durability: Steel’s Achilles Heel, Fiberglass’s Strength

Steel’s biggest weakness is its susceptibility to corrosion. When exposed to moisture and certain chemicals, steel rebar can rust, compromising the structural integrity of the concrete. This necessitates the use of galvanized steel or protective coatings, adding extra cost and complexity.

Fiberglass rebar, on the other hand, is essentially immune to corrosion. This eliminates the need for coatings and reduces the risk of structural failure due to rust. Additionally, fiberglass rebar offers superior resistance to fatigue and impact, making it a strong contender for long-term durability.

Special Considerations: A Look Beyond Strength

While strength and durability are crucial factors, other considerations can influence your choice:

- Thermal Efficiency: Fiberglass is a poor conductor of heat, making it ideal for structures in extreme temperature environments.

- Radio Frequency Transparency: Fiberglass allows radio waves to pass through, beneficial for hospitals and telecommunication facilities.

- Design Flexibility: Fiberglass rebar’s lighter weight and flexibility can be advantageous for complex architectural designs.

The Verdict: It Depends on Your Project

Both steel and fiberglass rebar offer distinct advantages. Steel remains a solid choice for projects requiring maximum tensile strength and a proven track record. However, fiberglass rebar’s lighter weight, superior corrosion resistance, and design flexibility make it a compelling option for many applications.

Choosing the right rebar for your project requires careful consideration of your specific needs. Consult with a structural engineer to determine the optimal material based on factors like load requirements, environmental conditions, and budget.

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!