+8613776545860

Innovation in construction materials has always been a driving force behind safer, more sustainable, and cost-effective building practices. Enter fiberglass rebar – a game-changer in the construction industry. In this comprehensive guide, we’ll delve into the world of fiberglass rebar, exploring its benefits, applications, and why it’s the go-to choice for modern infrastructure projects.

Why Fiberglass Rebar?

Fiberglass rebar, also known as GFRP (Glass Fiber Reinforced Polymer) rebar, is engineered to provide superior strength and durability compared to traditional steel reinforcement. Made from high-strength glass fibers embedded in a polymer resin matrix, fiberglass rebar offers several advantages:

Corrosion Resistance: Unlike steel rebar, which corrodes over time when exposed to moisture and chemicals, fiberglass rebar is impervious to corrosion. This inherent resistance extends the lifespan of structures, particularly in harsh environments such as marine or coastal areas.

Lightweight: Fiberglass rebar is significantly lighter than steel, making it easier to transport, handle, and install on construction sites. Its lightweight nature also reduces labor costs and minimizes the need for heavy lifting equipment.

High Strength-to-Weight Ratio: Despite being lightweight, fiberglass rebar boasts a high strength-to-weight ratio, providing exceptional tensile strength to reinforce concrete structures effectively.

Non-Conductive: Unlike steel rebar, fiberglass rebar is non-conductive, making it an ideal choice for applications where electrical conductivity is a concern, such as bridge decks and industrial facilities.

Thermal Insulation: Fiberglass rebar offers thermal insulation properties, reducing the risk of thermal bridging in concrete structures. This feature helps improve energy efficiency and enhances the overall performance of buildings.

Applications of Fiberglass Rebar:

The versatility of fiberglass rebar makes it suitable for a wide range of applications across various industries, including:

Infrastructure Projects: From bridges and highways to tunnels and dams, fiberglass rebar is widely used in infrastructure projects where corrosion resistance and durability are paramount.

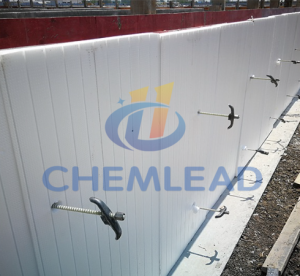

Residential Construction: Fiberglass rebar is increasingly being incorporated into residential construction for applications like foundation slabs, retaining walls, and swimming pools, offering homeowners a durable and low-maintenance solution.

Industrial Facilities: Industries such as chemical processing, wastewater treatment, and power generation rely on fiberglass rebar to withstand corrosive environments and ensure the longevity of critical structures.

Transportation: Fiberglass rebar is gaining popularity in transportation projects, such as railway platforms and airport runways, where its lightweight properties help reduce construction time and costs.

Marine Construction: In marine environments exposed to saltwater and moisture, fiberglass rebar outperforms steel rebar, making it the preferred choice for docks, seawalls, and offshore structures.

Fiberglass rebar represents a paradigm shift in construction materials, offering unmatched durability, corrosion resistance, and versatility across various applications. As the demand for sustainable and resilient infrastructure continues to grow, fiberglass rebar emerges as the go-to solution for engineers, architects, and contractors alike. Embrace the future of construction with fiberglass rebar and elevate your projects to new heights of excellence.

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!