+8613776545860

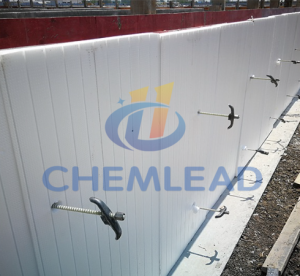

Fiberglass Rebar in Precast Concrete Walls: A Durable and Sustainable Choice

Introduction

When it comes to constructing precast concrete walls, choosing the right reinforcement material is crucial. Traditionally, steel rebar has been the go-to choice, but there’s an alternative that offers significant advantages: fiberglass rebar. In this blog post, we’ll explore why fiberglass rebar is gaining popularity in precast applications and how it can enhance the durability and longevity of your concrete structures.

What Is Fiberglass Rebar?

Fiberglass rebar, also known as FRP (Fiber-Reinforced Polymer) rebar, is a structural reinforcing rod made from a combination of fiberglass roving and resin. Unlike traditional steel rebar, which is susceptible to corrosion, FRP rebar offers several key benefits:

- Non-Corrosive: FRP rebar does not rust or corrode, making it ideal for applications where exposure to moisture, chemicals, or salt is a concern.

- High Tensile Strength: Despite its lightweight nature, fiberglass rebar has impressive tensile strength, comparable to steel.

- Non-Conductive: FRP rebar does not conduct electricity, making it suitable for structures where electrical interference is an issue.

- Lightweight: FRP rebar weighs only a fraction of steel, making handling and installation easier.

- Durability: Properly reinforced FRP concrete slabs exposed to heavy traffic can last approximately 20 times longer than conventional methods.

Advantages of Using Fiberglass Rebar in Precast Walls

1. Corrosion Resistance

Precast concrete structures are susceptible to corrosion, especially in aggressive environments. By using fiberglass rebar, which has zero metal content, you can significantly extend the lifespan of your precast walls. Unlike steel, FRP rebar does not corrode, ensuring long-term durability and reduced maintenance costs.

2. Improved Durability

FRP rebar’s corrosion resistance translates to improved durability. Concrete structures reinforced with fiberglass rebar experience minimal spalling and concrete degradation. Whether it’s basement walls, bridge decks, or driveways, FRP-reinforced concrete stands the test of time.

3. Ease of Installation

Handling and installing fiberglass rebar is simpler due to its lightweight nature. Contractors benefit from reduced labor hours, making projects more cost-effective. Additionally, FRP rebar doesn’t require expensive overlays or admixtures, further streamlining the construction process.

4. Long-Term Cost Savings

While the initial cost of FRP rebar may be slightly higher than steel, the long-term benefits outweigh the investment. Reduced maintenance, extended service life, and improved durability contribute to significant cost savings over the structure’s lifetime.

Design Considerations

When incorporating fiberglass rebar into precast walls, consider the following:

- Code Compliance: Blend the ACI 332 code for structural concrete with the ACI 440 guide for fiberglass rebar design. This ensures compliance while maximizing cost savings.

- Material Properties: Understand the material properties of fiberglass rebar, including tensile strength, modulus of elasticity, and creep behavior.

- Software Tools: Utilize readily available software tools that streamline the design process, making the transition from steel to FRP rebar seamless.

Conclusion

Fiberglass rebar offers a sustainable and forward-thinking solution for precast concrete walls. Its non-corrosive properties, ease of installation, and long-term durability make it an excellent choice for engineers, contractors, and project owners. As the construction industry continues to evolve, embracing innovative materials like FRP rebar ensures resilient and cost-effective structures.

Remember, when it comes to precast walls, think beyond steel—think fiberglass rebar! 🌟

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!